Hydroxypropyl methylcellulose ten questions

1. Hydroxypropyl methylcellulose is a nonionic cellulose ether. So what is nonionic?

Generally speaking, non-ion is a substance that does not ionize in water.

Ionization refers to the process by which an electrolyte is dissociate into a freely moving charged ion in a specific solvent.

For example, the salt-sodium chloride that is eaten every day is dissolved in water. Ionization produces free-moving sodium ions with positive and negative chloride ions. In other words, HPMC is placed in the water. It does not dissociate into charged ions, but exists in molecular form.

2. What is the gel temperature of hydroxypropyl methylcellulose?

The gel temperature of HPMC is related to its methoxy content. The lower the methoxy group content, the higher the gel temperature.

3. There is no relationship between the powder of putty powder and hydroxypropyl methylcellulose.

The powder of putty powder is mainly related to the quality of gray calcium. There is not much relationship with HPMC. The low calcium content of ash calcium and the CaO and Ca(OH)2 ratio of ash calcium are not suitable, so will cause powder loss.

If it is related to HPMC. Then, if the water retention of HPMC is poor, it will also cause powder loss.

4. What is the difference between the cold water instant solution and the hot melt type of hydroxypropyl methylcellulose in the production process?

The cold water instant type of HPMC is surface treated with glyoxal and quickly dispersed in cold water. It is not really dissolved, the viscosity comes up, it is dissolved.

The hot soluble form is not surface treat with glyoxal. When the amount of glyoxal is large, the dispersion is fast. But the viscosity is slower and the amount is small, the opposite is true.

5. What is the smell of hydroxypropyl methylcellulose?

The HPMC produced by the solvent method uses toluene and isopropanol as solvents. If the washing is not very good, there will be some residual taste.

6. Different uses, how to choose the right hydroxypropyl methylcellulose

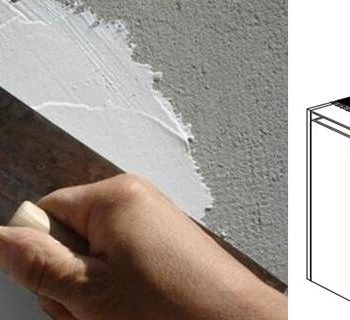

Application of putty powder: lower requirements, viscosity of 100,000, it will be fine. It is important to keep water.

Application of mortar: high requirements, high viscosity, 100,000 is better.

Glue application: Need instant type product, high viscosity.

7. What is the alias of hydroxypropyl methylcellulose?

Referred to as HPMC or MHPC alias hypromellose,and cellulose hydroxypropyl methyl ether.

8. The application of hydroxypropyl methylcellulose in putty powder, what is the cause of foam in putty powder?

In the putty powder, HPMC plays the role of thickening, water retention and construction. Do not participate in any reaction, so the reason for the bubble (1) too much water. (2) The bottom layer is not dry, and it is scraped on the top layer, and it is easy to foam.

9. What is the difference between hydroxypropyl methylcellulose and MC:

MC is methyl cellulose, which is treat with alkali after the refined cotton. so Using methyl chloride as an etherifying agent, a series of reactions are carried out to prepare a cellulose ether.

The general degree of substitution is 1.6-2.0. The degree of substitution differs depending on the solubility and belongs to the nonionic cellulose ether.

(1) The water retention of methyl cellulose depends on its addition amount, viscosity, particle fineness and dissolution rate. Generally, the amount of addition is large, the fineness is small, and the viscosity is large, and the water retention rate is high.

The addition amount has the greatest influence on the human water retention rate, and the viscosity level is not inferior to the water retention rate. So The rate of dissolution depends mainly on the degree of surface modification of the cellulose particles and the fineness of the particles.

Methylcellulose and hydroxypropylmethylcellulose have higher water retention rates in the above cellulose ethers.

(2) Methylcellulose is soluble in cold water, and it can be difficult to dissolve in hot water. The aqueous solution is very stable in the range of ph = 3-12, and is compatible with starch, and the like, as well as many surfactants. When the temperature reaches the gelation temperature, a gel phenomenon occurs.

(3) The change of temperature will seriously affect the water retention rate of methyl cellulose. Generally, the higher the temperature, the worse the water retention. If the temperature of the mortar exceeds 40 degrees, the water retention of methyl cellulose will be significantly deteriorate, which seriously affects the construction of the mortar.

(4) Methylcellulose has a significant effect on the workability and adhesion of the mortar. Adhesion here

Refers to the adhesive force felt between the worker’s application tool and the wall substrate.

That is, the shear resistance of the mortar. The adhesion is large, and the shear resistance of the mortar is large. The strength required by the workers during use is also large, and the construction of the mortar is poor.

10, the relationship between the viscosity of hydroxypropyl methylcellulose and temperature should be paid attention to in practical applications

The viscosity of HPMC is inversely proportional to temperature. That is, the viscosity increases as the temperature decreases. The viscosity of a product we usually say refers to the result of a 2% aqueous solution at a temperature of 20 degrees.

In practical applications, areas with large temperature differences between summer and winter. So It should be noted that it is recommended to use a relatively low viscosity in winter.

This is more conducive to construction, otherwise, when the temperature is low. The viscosity of cellulose will increase, and the hand feel will be heavy when scraped.

The medium viscosity of 75,000-100,000 is mainly use for putty.

Reason: Water retention is good.

The high viscosity of 15-20 million is mainly use for polystyrene granule insulation mortar powder and vitrified microbead hydrating mortar.

Reason: The viscosity is high, the mortar is not easy to fall and will sag,so improving the construction.

But in general, the higher the viscosity, the better the water retention. So many dry powder mortar plants take into account the cost. Medium and low viscosity cellulose was replace with medium viscosity cellulose ,so reduce the amount of addition.